NOTE: This information is for learning purposes only. We do not take responsibility for anything that happens to your vehicle as a result. Please use at your own risk!

Scan Tool use for starting your truck, how a Duramax idles, and balance rates

One of the rumors about using EFILive® is that you will blow things up if you don't know what you’re doing. While his can happen, it is not likely for someone who becomes familiar with data logging before they start tuning. Nobody has ever hurt an engine or transmission with a data logger. Data logging is the perfect way to become familiar with your vehicle while not changing anything that can break parts. The best part, the scan tool is included with the EFILive® software!

You should download and read the scan tool manual from EFILive®:

Or find it at Start=>Programs=>EFILive=>V7.5=>Documents=>Scan Tool Manual

Here is another tutorial regarding basic logging of a vehicle:

Or from the Scan Tool choose Help=>Tutorials=>Scan Tool Tutorial

The parameters you log are called PIDs. Here is some information about PIDs:

Diesels need a few things to run. Air, fuel, and compression come to the top of my head. Because a Duramax engine is controlled by electronics, it needs to monitor a lot of the engines operating parameters so it knows how to keep the engine running

For a Duramax to start, it uses the cam sensor as a reference to crank position so it knows which cylinders are coming up on compression. This enables the ECM to know which injector to start with. Once the computer gets a signal from the cam sensor, it begins the firing sequence. From then on the ECM monitors the crank position sensor to maintain the firing order. The cam sensor is only used to get the motor started.

Why is this important? Because you have some cam and crank sensor pulses missed PIDs you can log. This information can help you diagnose no start conditions. I've seen trucks that don't set cam or crank sensor codes have issues that can only be found by logging these PIDs. It's a good idea to become familiar with these PIDs when your truck is in good running order, that way the frustration of a truck that doesn't start does not get in the way of your finding the problem.

The cam and crank sensors are located on the front of the motor near the fan pulley and the crank pulley (balancer). The cam sensor is the upper one, the crank sensor is the lower one. The Duramax uses the crank sensor at idle to monitor the instantaneous RPM. The computer checks the RPM before and after each ignition event and it adjusts the injection amount of each cylinder to make the engines idle smooth.

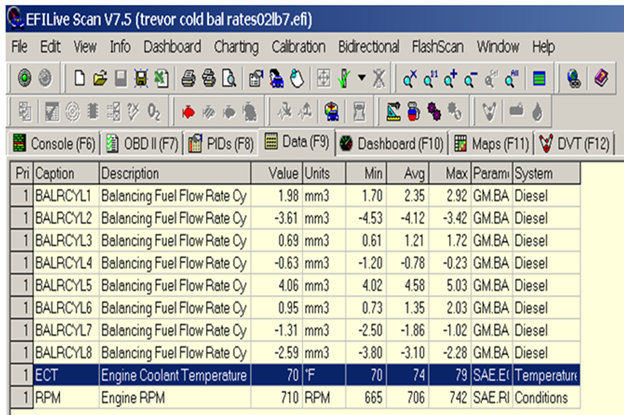

The difference between the commanded amount and the adjusted amount of fuel is described as the balance rate. When logging balance rates, you will see all zeros if the computer is not in idle mode. The Duramax computer (ECM) can't monitor balance rates if it is above idle or in fuel enrichment mode.

When in idle mode, you will see balance rate values between 15 and -15. These values represent the amount of fuel that needs to be added or subtracted from each cylinder to maintain a consistent idle rpm and consistent crank speed. A negative value means the computer is taking fuel away from that cylinder to maintain a smooth idle. A positive value means the computer is adding fuel to maintain a smooth idle.

A properly running engine will have values in the +3 to -3 range. Values above 3 and below -3 should be watched closely. Values above 6 and below -6 generally indicate some sort of injector or compression problem. Since the motor needs fuel, air, and compression to run, one can assume that there is a problem with at least one of those items. I’d say your balance rate reading is suspect.

Low compression on a cylinder will likely cause the ECM to call for more fuel to get it to keep up with the rest of the cylinders. A leaking injector might let too much fuel into a cylinder so it fires with more force than the others causing the ECM to lower the balance rate. Balance rates can be checked with hot or cold coolant temps. You should check them both neutral and in gear. Idling in gear will put some load on the engine and might allow a sneaky condition to show its ugly face. Balance rates are only an indicator; use the balance rate test to give you direction.

SAMPLE LOG WHEN CHECKING BALANCE RATES:

Suggested balance rate checking PIDs

OK DESCRIPTION CAPTION UNITS SYSTEM CH PARAMETER Y Balancing

Fuel Flow Rate Cylinder #1 BALRCYL1 mm3 Diesel 2 GM.BALRCYL1 Y Balancing

Fuel Flow Rate Cylinder #2 BALRCYL2 mm3 Diesel 2 GM.BALRCYL2 Y Balancing

Fuel Flow Rate Cylinder #3 BALRCYL3 mm3 Diesel 2 GM.BALRCYL3 Y Balancing

Fuel Flow Rate Cylinder #4 BALRCYL4 mm3 Diesel 2 GM.BALRCYL4 Y Balancing

Fuel Flow Rate Cylinder #5 BALRCYL5 mm3 Diesel 2 GM.BALRCYL5 Y Balancing

Fuel Flow Rate Cylinder #6 BALRCYL6 mm3 Diesel 2 GM.BALRCYL6 Y Balancing

Fuel Flow Rate Cylinder #7 BALRCYL7 mm3 Diesel 2 GM.BALRCYL7 Y Balancing

Fuel Flow Rate Cylinder #8 BALRCYL8 mm3 Diesel 2 GM.BALRCYL8 Y

Engine Coolant Temperature ECT °C,°F Temperature 1 SAE.ECT Y

Engine RPM RPM RPM Conditions 2 SAE.RPM

You should now have a better understanding of how your Duramax Diesel works and a "Starting Point" (no pun intended!) for becoming comfortable scanning your Duramax with EFILive®. Becoming comfortable logging your truck is the first step in getting your truck tuned to perfection. Logging is the best way to become familiar with EFILive® without risking any damage to your vehicle. Don’t be afraid. Scanning is fun and easy!! And even if you’ve purchased a locked ECM, you can still use the scan tool. Use it often, use it to ask your tuner questions, and get better results from refinement of your tunes. That is what EFILive® is all about!!!

BOB OLSON

TWISTED DIESEL TUNING

BOBOTUNE@ROCKETMAIL.COM

EFILIVE® BETA TESTER SINCE 2006